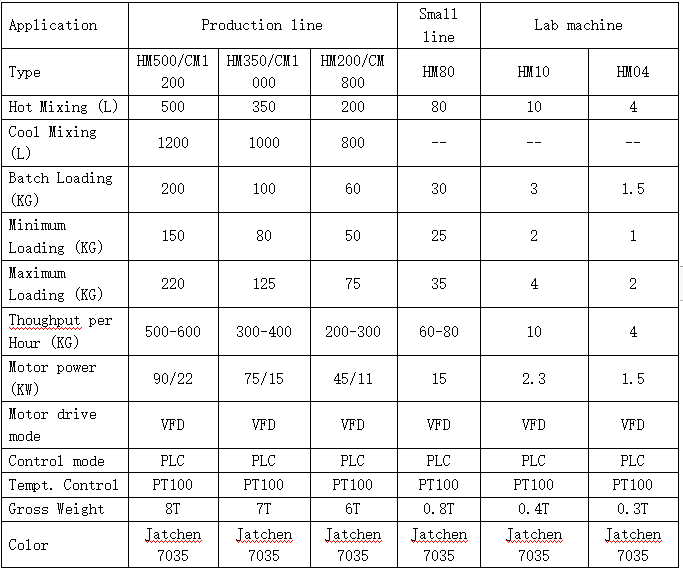

BDJ Series Bonding Mixing Machine is designed based on the leading technology from Germany, the sixth generation technology, adopting PLC control with high automation, multi-function and compact structure, it mixes the metal powder homogeneously, which is the the ideal equipment for high-end metal powder.

Features:

n Container design with cooling and hot water jacket.

n Propeller blade, easy to clean and change color

n Speed controlled by frequency inverter, displaying the temperature of chill water and hot water of the container

n Gas checking and controlling device

n Automatically controlled discharge valve

n Industrial control system with PLC touch screen

n Equipped with nitrogen generator(Optional)

n Anti-explosion protection system for mixing containers

Advantages

n Effectiveness of bonding

n Intelligence of process

n Reliable of equipment

n Safety of production

n Simplicity of operation

n Eliminating quality problem of coatings

² Effectiveness of bonding

Really effective bonding process is embodied in uniform mixing between basic material and metal pigment above Tg point for long time. Jatchen bonding system can guarantee bonding mix of general powder coatings for 3-5 min without caking at 65°C-70°C to as to achieve real bonding effect, and this is absolutely benefited from its professional design and precise control.

The bonging mixer is made of special steel which is mirror polished to avoid material sticking.

The distance between mixing tools and container wall is especially specified so as to avoid dead spaces in mixer

The mixing tools are designed into unique multi-layer structure to guarantee uniform mixing of all materials

The deflector is installed through the container lid to guarantee the optimized flow of material

Intelligent temperature control system enables precise control of material temperature during bonding process.

² Intelligence of process

Jatchen bonding system abandons conventional temperature control mode of creating heat by friction by changing the speed of mixing tools, but performs temperature control through heat exchange among multi-layer heat runners designed in mixer container. The whole process is under intelligent judgment and control of computer system,as a result, material temperature can be controlled precisely during bonding. Moreover,the bonding process is conducted at constant torque and shear force So as to avoid damage of high shear force to metallic flake pigment in conventional bonding machines, therefore, coatings with high-flash effect can be produced.

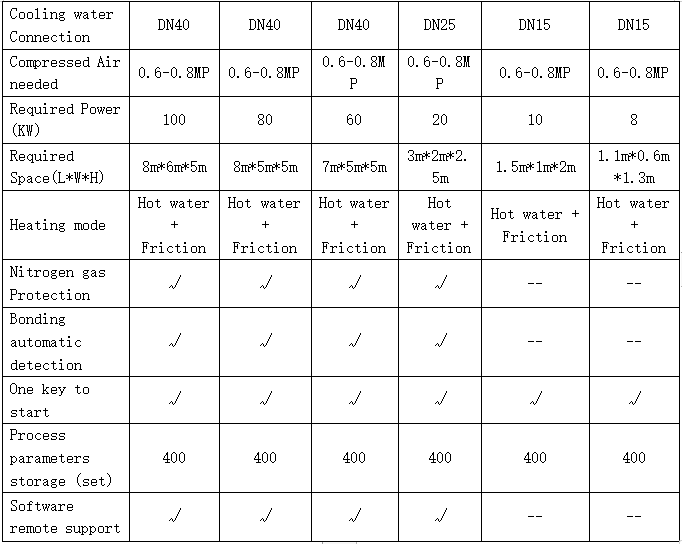

² Reliability of equipment

Jatchen bonding system, the driving system adopts SIEMENS motor and SIEMENS frequency converter, the control system adopts SIEMENS PLC and SIEMENS touch screen,low-voltage electric appliances are from Schneider,and pneumatic system is from Taiwan ARTIC. The whole configuration and reasonable design guarantee the reliability and safety of the system.

² Safety of production

During running of the whole system,oxygen monitoring and nitrogen protecting systems prevent the risk of dust explosion;All mechanical parts should be grounded reliably to guide away generated static immediately;At running and connecting parts of machinery sensors and interlocking mechanisms are set to guarantee reliability of connection and safety of operation.

² Simplification of operation

Jatchen bonding system takes automation of production process and simplicity of operation process into full account;The system can save various production process parameters of products for real-time call out to perform production,or can be networked with PC for centralized control and management;The whole operation is fufilled just by one key,and nitrogen detection,heating up,bonding,cooling and feeding processes are carried out automatically without operations by p personnel. Production modes are"divided into manual mode,trial production and mass production mode with convenience fortrial and production.

The discharge is designed in swing-way,easy to clean machinechange type.

² Eliminating quality problems of coatings

The bonding process can eliminate the following quality problems existing in conventional dry mixing process

Problems in coating

Poor leveling

Existence of sand

Existence of chromatic aberration

Liable to discolor

Problems in spraying

poor powder absorption

Liable to burn out spray gun

Useless recovery powde

We'll contact you

scan QR codescontact

More exciting waiting for you!

tel:86-535-611-0828 /86-535-611-0820

phone:18660059916 / 18561071331

mail:williamxing@jatchen.com

address : 48 Lishui Road, Menlou Industrial Park, Fushan District, Yantai

Copyright©2021 All rights reserved Yantai Jatchen 鲁ICP备12027359号-1 website building: 智推信息技术 Yantai