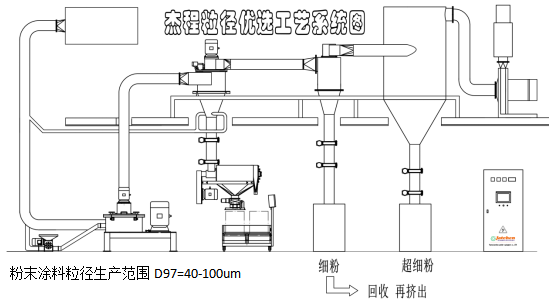

Yantai Jiecheng Powder Equipment Co., Ltd. researched and developed the patented equipment particle size optimization mill set. Through innovative optimization of grinding and grading technology, it solved the requirement of continuous growth of powder coating quality in the current powder coating production process, and has reached the level of advanced process equipment for powder coating production in the world.

In order to produce high-quality powder coating products, the pieces crushed by extrusion cooling must be graded by professional grinding and sorting equipment. Based on ACM EC easy-to-clean mill group, Yantai Jiecheng Powder Equipment Co., Ltd. developed the technology of particle size optimization and grading, which can effectively separate and adjust the content of fine powder less than 10um in the process of powder coating production, and produce high-quality powder coating products with very high particle size concentration, referred to as Jiecheng particle size optimization system for short. This equipment system of particle size optimization grinding technology provides the equipment foundation for high-quality Bo Tu and high-quality special coating in powder coating technology, which can meet the requirements of powder coating for special products and is the production technology system of the highest-quality powder coating.

Particle size is an important attribute of powder coatings, and the concentration of particle size directly determines the quality and performance of powder coatings. In view of the strict requirements of high-quality powder coatings on particle size concentration and the properties of powder coatings themselves, Jiecheng particle size optimization system has the following characteristics:

1. Have the ability to produce at least superfine special powder coatings;

2. Excellent particle size distribution and high concentration of particle size; Accurate and adjustable cutting precision;

3. Compact and space-saving design;

4. Easy to switch production mode; Easy to clean and maintain, especially suitable for frequent product replacement;

5. It can be combined with crushing equipment to form an online or offline production system;

At present, there is no problem in grinding powder coating into fine powder, but the problem is how to reduce the powder below 10um as much as possible to obtain ideal powder coating products. The Jiecheng particle size optimization system has well solved the problems of more fine powder below 10um, rising material temperature, storability and concentrated particle size in the process of high-efficiency grinding, and provided preconditions for obtaining ideal quality powder coating.

Jiecheng particle size optimization system can provide necessary process equipment for the production of the best quality powder coatings, and design humanized/easy cleaning and maintenance components and systems.

Data experiment table of Jiecheng particle size optimization system

| 薄涂型Thinfilmqualities | 标准型Standard qualities |

| 丙烯酸粉末涂料(Acrylic) | 环/聚/混(Epoxy/Polyester/hybrides) |

| D50=20um D99=50um | D50=32-40um D99=90-100um |

| 细粉减少到5-15%<10um | 3-5%<10um |

| 成品粉收率:80-95% | 95-99% |

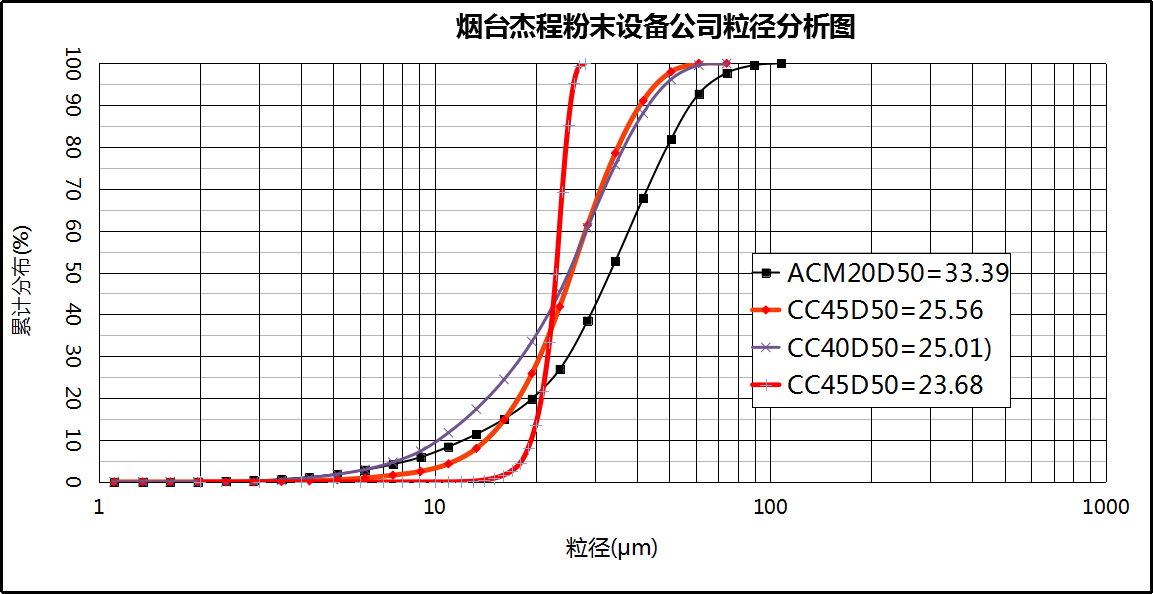

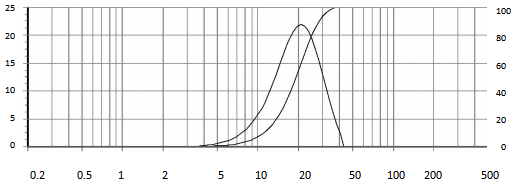

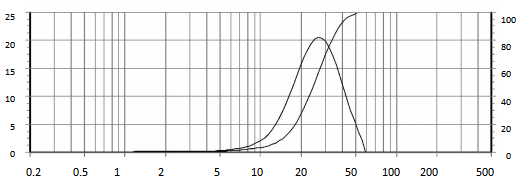

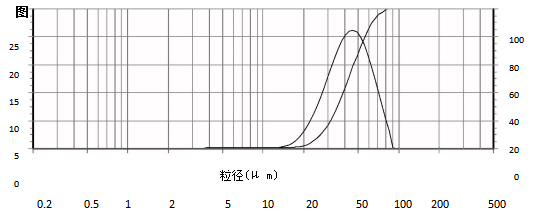

Jiecheng particle size optimization system provides equipment conditions for the production of ideal quality powder coatings. At present, it is well applied in the production of high-quality Bo Tu type and high-quality powder coatings, such as high-quality anticorrosive powder. See Table 1 to Table 4 for the particle size distribution data of powder coatings sample -1 to sample -4. The particle size distribution curve of powder coating is shown in Figures 1 to 4. See Table 5 for equipment configuration specifications of Jiecheng particle size optimization unit; Fig. 5 ACM02 laboratory mill for research and development.

Table 1. Particle size distribution of powder coating samples crushed by optimal grinding mill group

Granularity characteristic parameter

| D(4,3) | 19.48 m | D50 | 19.10 m | D(3,2) | 16.80 μm | S.S.A. | 0.36 sq.m/c.c. | |

| D10 | 10.90 μm | D25 | 14.73 μm | D75 | 23.80 μm | D90 | 28.65 μm | |

粒度分布表 |

||||||||

粒径 |

微分 | 累积分布 | 粒径 | 微分分布 | 累积分布 | 粒径 | 微分分布 | 累积分布 |

| (μm) | ( % ) | ( % ) | (μm) | ( % ) | ( % ) | (μm) | ( % ) | ( % ) |

| 0.2 | 2.89 | 0.01 | 0.01 | 41.84 | 2.56 | 99.75 | ||

| 0.24 | 0 | 0 | 3.5 | 0.04 | 0.05 | 50.64 | 0.25 | 100 |

| 0.29 | 0 | 0 | 4.24 | 0.16 | 0.21 | 61.28 | 0 | 100 |

| 0.35 | 0 | 0 | 5.13 | 0.35 | 0.55 | 74.17 | 0 | 100 |

| 0.43 | 0 | 0 | 6.21 | 0.72 | 1.27 | 89.76 | 0 | 100 |

| 0.52 | 0 | 0 | 7.51 | 1.36 | 2.63 | 108.63 | 0 | 100 |

| 0.63 | 0 | 0 | 9.09 | 2.44 | 5.07 | 131.47 | 0 | 100 |

| 0.76 | 0 | 0 | 11 | 5.19 | 10.25 | 159.11 | 0 | 100 |

| 0.92 | 0 | 0 | 13.31 | 9.04 | 19.3 | 192.57 | 0 | 100 |

| 1.11 | 0 | 0 | 16.11 | 14.12 | 33.42 | 233.06 | 0 | 100 |

| 1.35 | 0 | 0 | 19.5 | 18.95 | 52.36 | 282.06 | 0 | 100 |

| 1.63 | 0 | 0 | 23.6 | 21.94 | 74.3 | 341.36 | 0 | 100 |

| 1.97 | 0 | 0 | 28.56 | 15.44 | 89.74 | 413.14 | 0 | 100 |

| 2.39 | 0 | 0 | 34.57 | 7.45 | 97.2 | 500 | 0 | 100 |

|

Table 2 -2 Particle size distribution of powder coating samples crushed by optimal grinding mill group

|

|||||||||||||

| D(4,3) 25.80 μm | D50 25.00 μm | D(3,2) 20.56 μm | S.S.A. 0.29 sq.m/c.c. | ||||||||||

| D10 14.50 μm | D25 19.11 μm | D75 31.97 μm | D90 38.41 μm | ||||||||||

|

粒径分布表 |

|||||||||||||

| 粒径 | 微分分布 | 累积分布 | 粒径 | 微分分布 | 累积分布 | 粒径 | 微分分布 | 累积分布 | |||||

| (μm) | ( % ) | ( % ) | (μm) | ( % ) | ( % ) | (μm) | ( % ) | ( % ) | |||||

| 0.2 | 2.89 | 0.03 | 0.52 | 41.84 | 11.55 | 93.2 | |||||||

| 0.24 | 0 | 0 | 3.5 | 0.05 | 0.58 | 50.64 | 5.55 | 98.76 | |||||

| 0.29 | 0 | 0 | 4.24 | 0.11 | 0.69 | 61.28 | 1.24 | 100 | |||||

| 0.35 | 0 | 0 | 5.13 | 0.2 | 0.89 | 74.17 | 0 | 100 | |||||

| 0.43 | 0 | 0 | 6.21 | 0.37 | 1.25 | 89.76 | 0 | 100 | |||||

| 0.52 | 0 | 0 | 7.51 | 0.61 | 1.86 | 108.63 | 0 | 100 | |||||

| 0.63 | 0 | 0 | 9.09 | 0.92 | 2.79 | 131.47 | 0 | 100 | |||||

| 0.76 | 0 | 0 | 11 | 1.68 | 4.47 | 159.11 | 0 | 100 | |||||

| 0.92 | 0 | 0 | 13.31 | 3.6 | 8.07 | 192.57 | 0 | 100 | |||||

| 1.11 | 0.02 | 0.02 | 16.11 | 7.06 | 15.13 | 233.06 | 0 | 100 | |||||

| 1.35 | 0.1 | 0.12 | 19.5 | 11.67 | 26.81 | 282.06 | 0 | 100 | |||||

| 1.63 | 0.18 | 0.3 | 23.6 | 16.98 | 43.78 | 341.36 | 0 | 100 | |||||

| 1.97 | 0.12 | 0.43 | 28.56 | 20.57 | 64.35 | 413.14 | 0 | 100 | |||||

| 2.39 | 0.06 | 0.49 | 34.57 | 17.3 | 81.65 | 500 | 0 | 100 | |||||

表3 杰程粒径优选磨粉机组粉碎粉末涂料样品-3粒度分布

| 粒度特征参数 | |||||

| D(4,3) 35.20 um | D50 34.23 μm | D(3,2) | 29.48 μm | S.S.A.0.20 sq.m/c.c. | |

| D10 20.31 μm | D25 26.54 μm | D75 | 43.18 μm | D90 52.08 μm | |

| 粒径分布表 | ||||||||

| 粒径 | 微分分布 | 累积分布 | 粒径 | 微分分布 | 累积分布 | 粒径 | 微分分布 | 累积分布 |

| (μm) | ( % ) | ( % ) | (μm) | ( % ) | ( % ) | (μm) | ( % ) | ( % ) |

| 0.2 | 2.89 | 0.03 | 0.06 | 34.57 | 20.25 | 51.12 | ||

| 0.24 | 0 | 0 | 3.5 | 0.11 | 0.17 | 41.84 | 20.66 | 71.77 |

| 0.29 | 0 | 0 | 4.24 | 0.22 | 0.4 | 50.64 | 16.83 | 88.61 |

| 0.35 | 0 | 0 | 5.13 | 0.16 | 0.55 | 61.28 | 9.26 | 97.86 |

| 0.43 | 0 | 0 | 6.21 | 0.1 | 0.65 | 74.17 | 1.75 | 99.62 |

| 0.52 | 0 | 0 | 7.51 | 0.11 | 0.76 | 89.76 | 0.38 | 100 |

| 0.63 | 0 | 0 | 9.09 | 0.24 | 0.99 | 108.63 | 0 | 100 |

| 0.76 | 0 | 0 | 10 | 0.31 | 1.31 | 131.47 | 0 | 100 |

| 0.92 | 0 | 0 | 11 | 0.32 | 1.62 | 159.11 | 0 | 100 |

| 1.11 | 0.01 | 0.01 | 13.31 | 1.14 | 2.77 | 192.57 | 0 | 100 |

| 1.35 | 0.01 | 0.02 | 16.11 | 1.98 | 4.75 | 233.06 | 0 | 100 |

| 1.63 | 0.01 | 0.03 | 19.5 | 3.75 | 8.5 | 282.06 | 0 | 100 |

| 1.97 | 0 | 0.03 | 23.6 | 7.11 | 15.61 | 341.36 | 0 | 100 |

| 2.39 | 0 | 0.04 | 28.56 | 15.26 | 30.87 | 413.14 | 0 | 100 |

Table 4 The particle size of the powder coating samples crushed by the optimal grinding mill group -4 Particle size distribution

| 粒度特征参数 | |||||||

| D(4,3) 43.90 μm | D50 42.49 μm | D(3,2) 37.91 μm | S.S.A. | 0.16 sq.m/c.c. | |||

| D10 25.98 μm | D25 33.02 μm | D75 53.57 μm | D90 64.04 μm | ||||

| 粒径分布表 | ||||||||

| 粒径 | 微分分布 | 累积分布 | 粒径 | 微分分布 | 累积分布 | 粒径 | 微分分布 | 累积分布 |

| (μm) | ( % ) | ( % ) | (μm) | ( % ) | ( % ) | (μm) | ( % ) | ( % ) |

| 0.2 | 2.89 | 0.01 | 0.01 | 41.84 | 19.3 | 48.23 | ||

| 0.24 | 0 | 0 | 3.5 | 0.04 | 0.05 | 50.64 | 21.19 | 69.42 |

| 0.29 | 0 | 0 | 4.24 | 0.09 | 0.14 | 61.28 | 18.63 | 88.05 |

| 0.35 | 0 | 0 | 5.13 | 0.1 | 0.25 | 74.17 | 8.44 | 96.49 |

| 0.43 | 0 | 0 | 6.21 | 0.12 | 0.37 | 89.76 | 2.89 | 99.38 |

| 0.52 | 0 | 0 | 7.51 | 0.15 | 0.52 | 108.63 | 0.62 | 100 |

| 0.63 | 0 | 0 | 9.09 | 0.16 | 0.68 | 131.47 | 0 | 100 |

| 0.76 | 0 | 0 | 11 | 0.07 | 0.74 | 159.11 | 0 | 100 |

| 0.92 | 0 | 0 | 13.31 | 0.02 | 0.76 | 192.57 | 0 | 100 |

| 1.11 | 0 | 0 | 16.11 | 0.3 | 1.06 | 233.06 | 0 | 100 |

| 1.35 | 0 | 0 | 19.5 | 1.26 | 2.33 | 282.06 | 0 | 100 |

| 1.63 | 0 | 0 | 23.6 | 3.25 | 5.58 | 341.36 | 0 | 100 |

| 1.97 | 0 | 0 | 28.56 | 8.79 | 14.36 | 413.14 | 0 | 100 |

| 2.39 | 0 | 0 | 34.57 | 14.57 | 28.93 | 500 | 0 | 100 |

1, which can be well applied to Bo Tu powder coatings, such as the coating range of paint powder;

The particle sizes of powder coatings of sample 2 and sample 3 can belong to conventional high-quality powder coatings; Have a wide range of coating;

The particle size of powder coating of sample 4 can be well applied to anticorrosive powder coating, such as the coating range of steel powder;

All of the above samples are measured by the customer sample powder from Europe and America LS-POP6 laser particle size analyzer.

Table 5 Equipment configuration specification of Bo Tu for particle size optimization system of Yantai Jiecheng Powder Equipment Co., Ltd.

| 粒径优选分级机 | 研磨机 |

风 量 M3/h |

薄涂粉产量 Kg/h |

常规粉产量 Kg/h |

分级功率 KW |

| CC02 | ACM02 | 260 | 2 | 5 | 0.37 |

| CC05 | ACM05 | 510 | 30 | 50 | 2.2 |

| CC45 | ACM30 | 2700 | 220 | 500 | 7.5 |

| CC60 | ACM40 | 3600 | 350 | 720 | 11 |

(The output in the table is calculated according to the standard formula of industrial society powder coatings, and is related to the particle size concentration and formula, for reference only)

The powder coating produced by Jiecheng particle size optimization grinding unit has the following characteristics:

1. The particle size of the powder coating can be adjusted to the least superfine part of the special powder coating, and the uniformity of the coating film is improved;

2. Increasing the powder feeding rate;

3. The spraying area is increased;

4. The glossiness is improved;

5. Improve the production efficiency of spraying production line and speed of spraying line;

6. Good powder rate on the internal corner of the workpiece;

7. Reduce agglomeration of powder coating and improve storage performance;

8. Improve the cleanliness of the spraying environment, and significantly reduce PM2.5;

9. Increase the fluidity of powder coating without blocking the gun;

10. Reduce the dosage of related additives.

The concentration degree of powder particle size is a way to express the concentration degree of powder particle size intuitively.

The formula is as follows:

Particle size concentration of powder coating C=2×D50/(D90-D10)

The larger the concentration value, the more concentrated the particle size of powder coating. High concentration of powder coatings is an important feature of high-quality powder coatings.

The concentration degree of powder coatings has been applied in the technical management system of large and medium-sized powder coatings production, and has become an important part of big data of powder coatings production enterprises.

Particle size concentration degree of powder coating is a way to express the concentration degree of powder particle size intuitively,

The formula is as follows:

Particle size concentration of powder coating C=2×D50/(D90-D10)

The larger the concentration value, the more concentrated the particle size of powder coating. High concentration of powder coatings is an important feature of high-quality powder coatings.

The concentration degree of powder coatings has been applied in the technical management system of large and medium-sized powder coatings production, and has become an important part of big data of powder coatings production enterprises.

Particle size concentration degree of powder coating is a way to express the concentration degree of powder particle size intuitively,

The formula is as follows:

Particle size concentration of powder coating C=2×D50/(D90-D10)

The larger the concentration value, the more concentrated the particle size of powder coating. High concentration of powder coatings is an important feature of high-quality powder coatings.

The concentration degree of powder coatings has been applied in the technical management system of large and medium-sized powder coatings production, and has become an important part of big data of powder coatings production enterprises. Components;

Yantai Jiecheng Powder Equipment Co., Ltd. researched and developed the patented equipment particle size optimization mill set. Through innovative optimization of grinding and grading technology, it solved the requirement of continuous growth of powder coating quality in the current powder coating production process, and has reached the level of advanced process equipment for powder coating production in the world.

In order to produce high-quality powder coating products, the pieces crushed by extrusion cooling must be graded by professional grinding and sorting equipment. Based on ACM EC easy-to-clean mill group, Yantai Jiecheng Powder Equipment Co., Ltd. developed the technology of particle size optimization and grading, which can effectively separate and adjust the content of fine powder less than 10um in the process of powder coating production, and produce high-quality powder coating products with very high particle size concentration, referred to as Jiecheng particle size optimization system for short. This equipment system of particle size optimization grinding technology provides the equipment foundation for high-quality Bo Tu and high-quality special coating in powder coating technology, which can meet the requirements of powder coating for special products and is the production technology system of the highest-quality powder coating.Particle size is an important attribute of powder coatings, and the concentration of particle size directly determines the quality and performance of powder coatings. In view of the strict requirements of high-quality powder coatings on particle size concentration and the properties of powder coatings themselves, Jiecheng particle size optimization system has the following characteristics:

1. Have the ability to produce at least superfine special powder coatings;

2. Excellent particle size distribution and high concentration of particle size; Accurate and adjustable cutting precision;

3. Compact and space-saving design;

4. Easy to switch production mode; Easy to clean and maintain, especially suitable for frequent product replacement;

5. It can be combined with crushing equipment to form an online or offline production system;

At present, there is no problem in grinding powder coating into fine powder, but the problem is how to reduce the powder below 10um as much as possible to obtain ideal powder coating products. The Jiecheng particle size optimization system has well solved the problems of more fine powder below 10um, rising material temperature, storability and concentrated particle size in the process of high-efficiency grinding, and provided preconditions for obtaining ideal quality powder coating.

Jiecheng particle size optimization system can provide necessary process equipment for the production of the best quality powder coatings, and design humanized/easy cleaning and maintenance components and systems.

Data experiment table of Jiecheng particle size optimization systemJiecheng particle size optimization system provides equipment conditions for the production of ideal quality powder coatings. At present, it is well applied in the production of high-quality Bo Tu type and high-quality powder coatings, such as high-quality anticorrosive powder. See Table 1 to Table 4 for the particle size distribution data of powder coatings sample -1 to sample -4. The particle size distribution curve of powder coating is shown in Figures 1 to 4. See Table 5 for equipment configuration specifications of Jiecheng particle size optimization unit; Fig. 5 ACM02 laboratory mill for research and development.

Table 1. Particle size distribution of powder coating samples crushed by optimal grinding mill group

Granularity characteristic parameters

We'll contact you

scan QR codescontact

More exciting waiting for you!

tel:86-535-611-0828 /86-535-611-0820

phone:18660059916 / 18561071331

mail:williamxing@jatchen.com

address : 48 Lishui Road, Menlou Industrial Park, Fushan District, Yantai

Copyright©2021 All rights reserved Yantai Jatchen 鲁ICP备12027359号-1 website building: 智推信息技术 Yantai